Research center

Customer: Ferrari S.p.A.

Years: 2001 – 2004 (Built)

Activities: Preliminary and Detailed Design (MEP Engineering), Control of worker’s safety on site (HSE), Site Supervision (MEP Engineering)

Project cost: Euro 14.9 mln of works

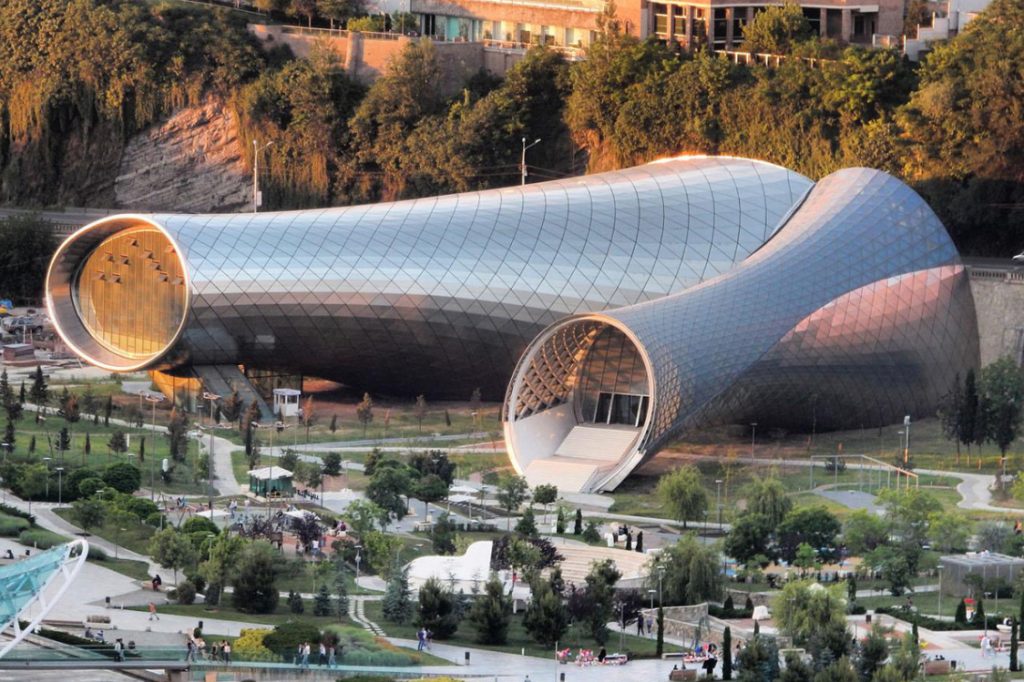

Architecture: Massimiliano Fuksas

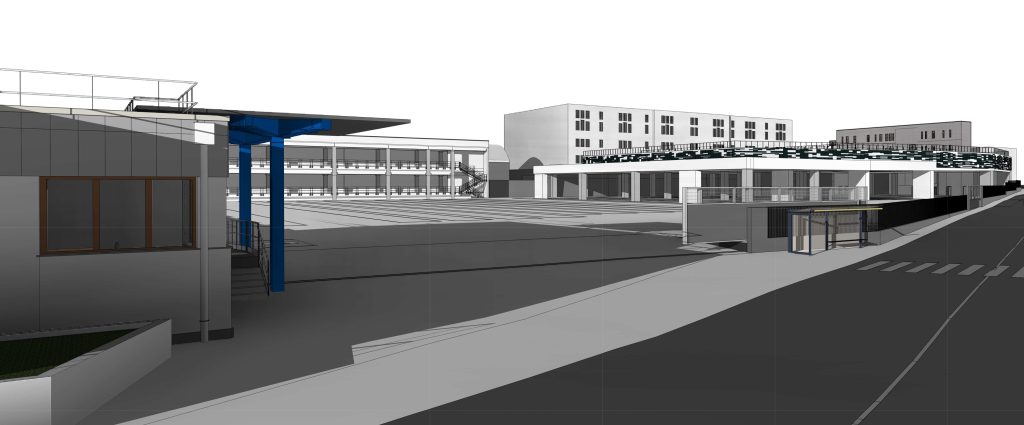

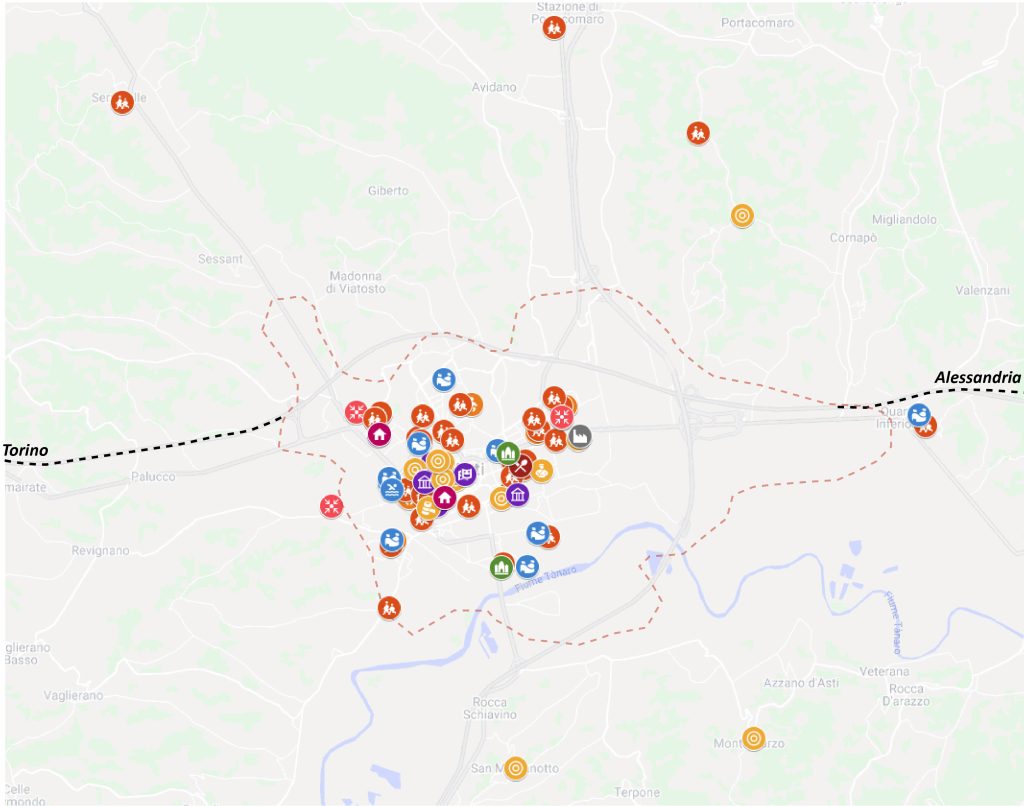

The 13,000-square-meter building houses the offices of the Ferrari Product Development Center and is located within the “Ferrari Citadel” in Maranello (Modena), near the main entrance to the plant between the New Wind Tunnel and the New Mechanical Workshop.

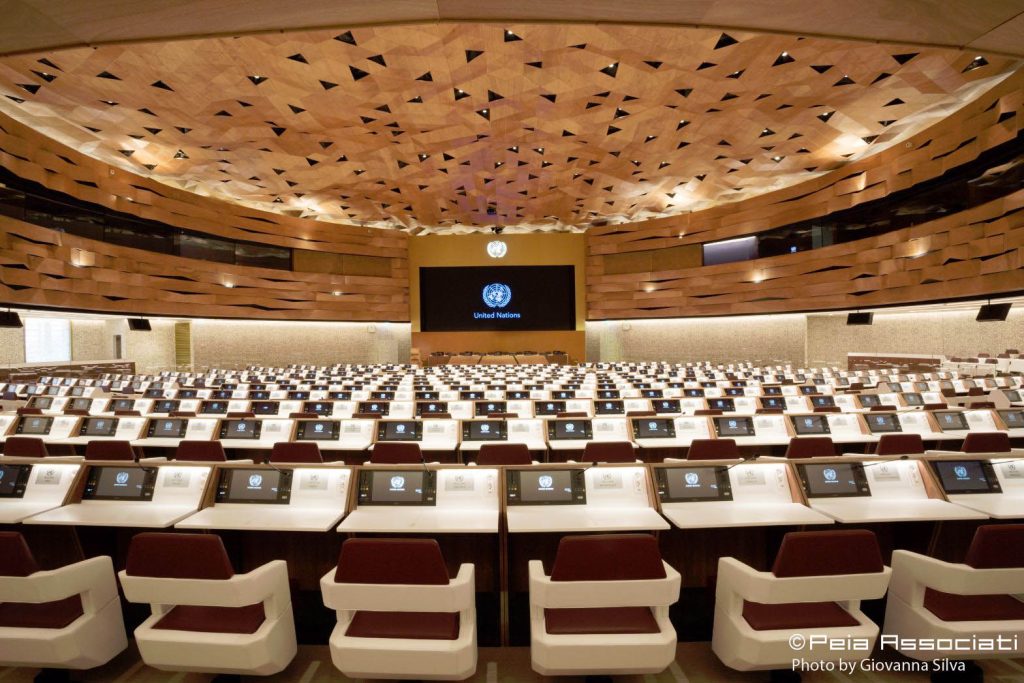

According to the Client’s requirements, the project aimed to meet the need to create a working environment with a strong image and representative for the company. A work place with spacious and illuminated proportions, functional for the processes of research, design and implementation. The structure is divided into two architectural volumes lying on top of each other, separated horizontally by an open “water plane” completely on pilotis, designed to house the Maranello company’s displays. The various rooms, designed to facilitate the rapid exchange of information among the teams, are arranged on four levels: a large ground floor used for meeting rooms and services; a basement for technical rooms, storage and archives; a raised “water plane” that houses the exhibition areas; and a second floor reserved for offices and large open spaces. The second floor, a square-based parallelepiped “suspended” over the water plane, is 70 meters on a side and 4.20 meters high. Here, thanks to a series of open internal courtyards, the various offices face each other, allowing natural light to illuminate the rooms on the lower floors.

From the plant engineering point of view, the interior rooms are provided with floating floors and technological suspended ceilings, integrated into the system of mechanical and electrical fluid systems. The air-conditioning system in the offices and meeting rooms is based on primary air supply through floating floors, with floor convectors for winter heating and radiant ceiling panels with chilled water to counter endogenous and summer heat loads. To ensure complete climate control and indoor air filtration, the glazed facades are fixed non-opening type. The planned air-conditioning system has one of its strengths in its flexibility and modularity, which makes it possible to ensure occupants’ comfort conditions even after changes in space configuration. The water veil also allows evaporative cooling in the summer season, benefiting the floor below. The water can be used for cooling the condensers of the refrigeration units. Almost completely glazed, the two parallelepipeds are buffered with cellular facades that allow maximum transparency with a great reduction in energy transmission, in favor of good visual, light, thermal and acoustic comfort. Inside, there are curtains that further enhance performance and allow regulation of light intensity.