New area for worship, guest house and general services including the restoration of the cascina viscontea “La guardia di sopra”

Historical building | XVI Century

Customer: Istituto Buddista Italiano Soka Gakkai (IBISG)

Years: 2008 – 2014 (Built)

Activities: Preliminary and Final Design (Structural and MEP Engineering), Control of worker’s safety on site (HSE), Emergency planning of the existing abandoned complex, Site Supervision

Project cost: Euro 12.0 mln of works

Architecture by: Peia Associati

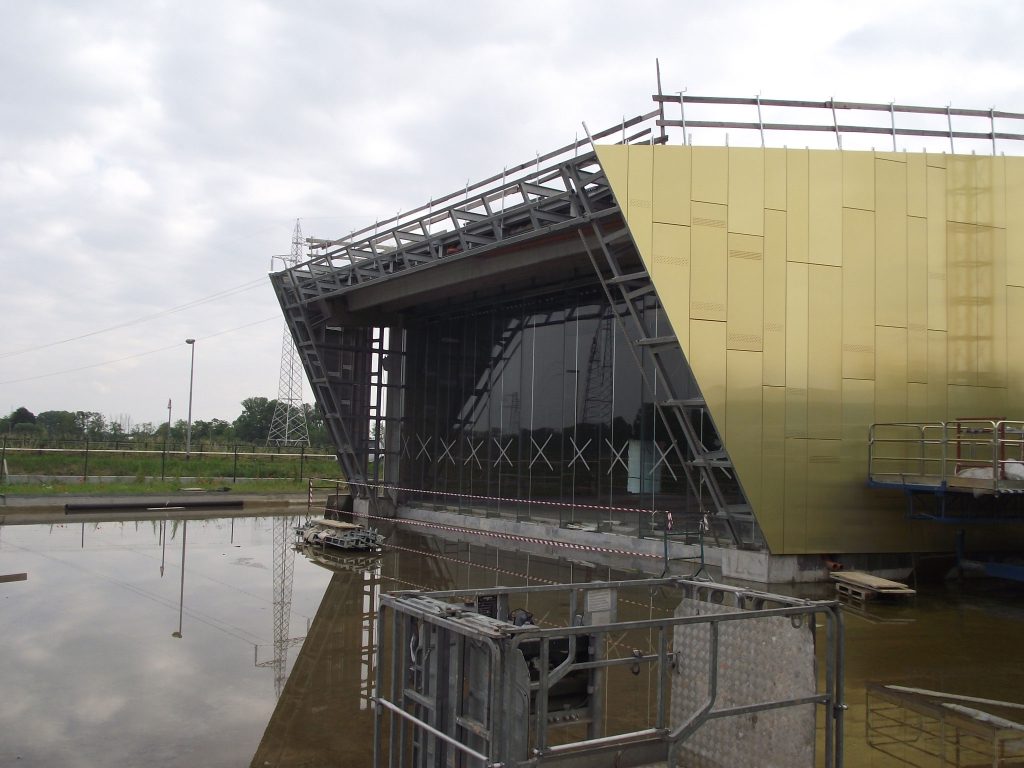

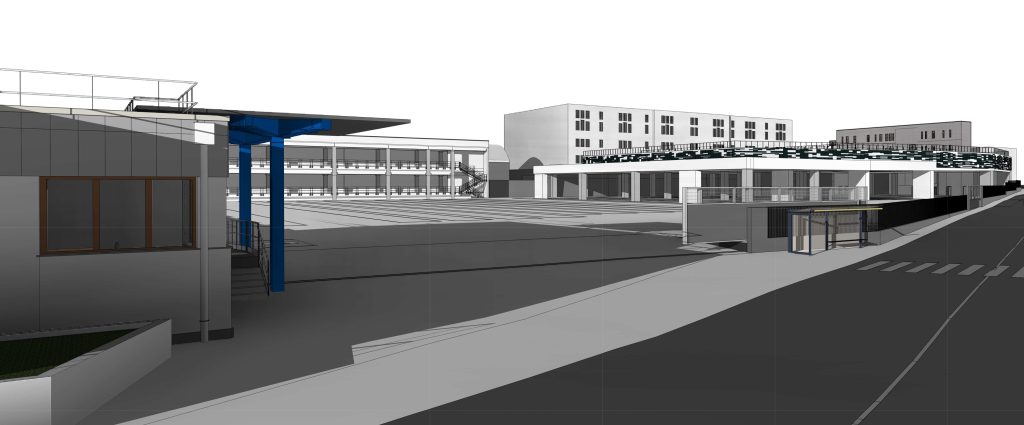

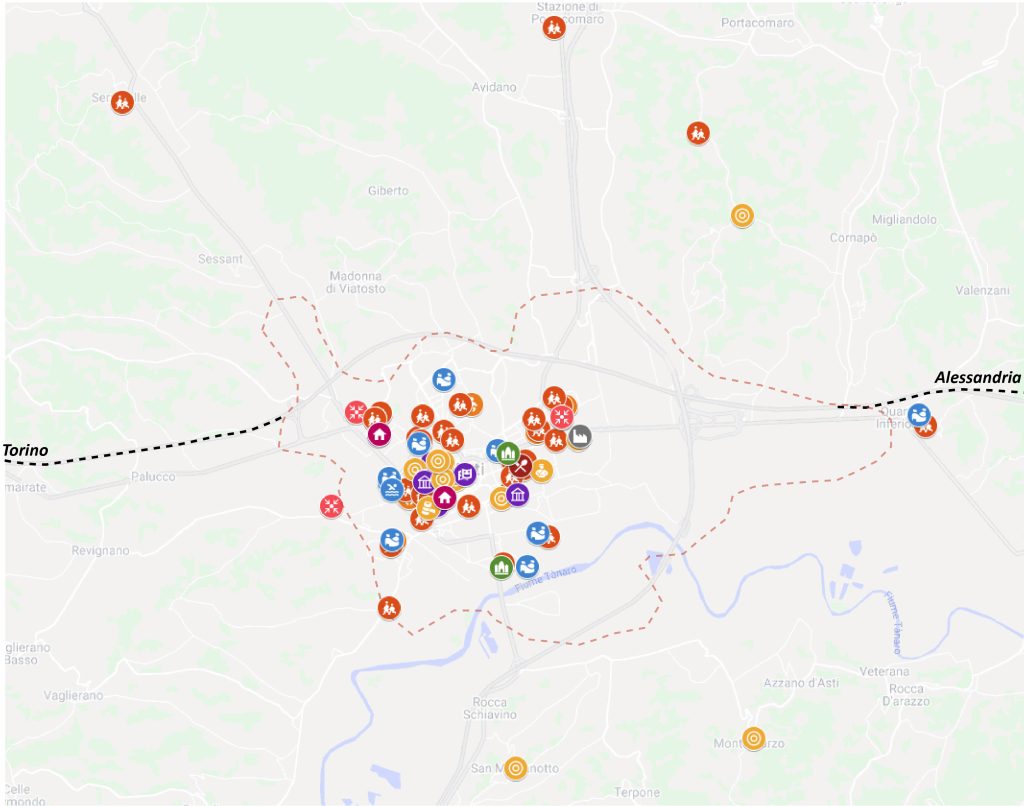

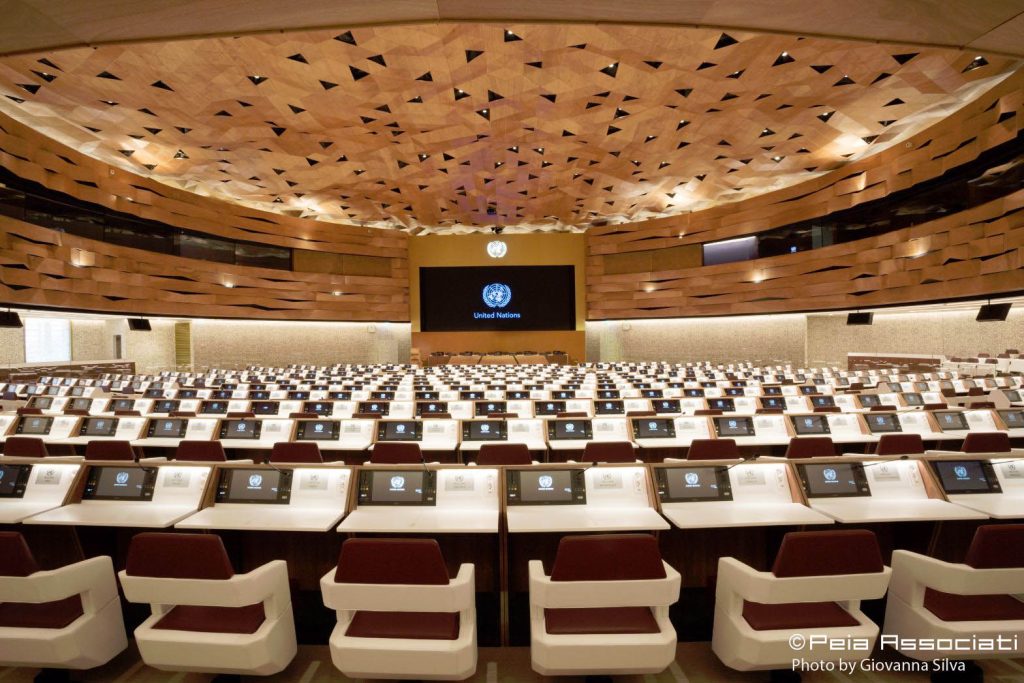

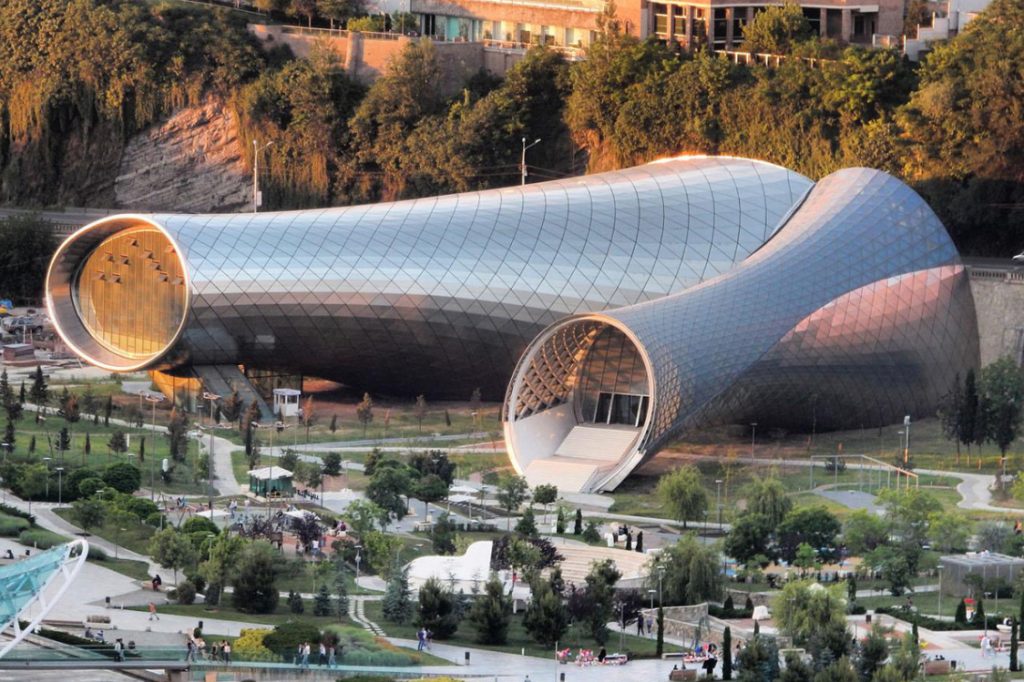

The project for the “Ikeda Cultural Center for Peace,” reflects a coherent relationship between history and contemporaneity, in an area marked by strong settlement and transformation connotations: on the one hand, the monumental complex of the Visconti farmstead “La Guardia di Sopra,” and on the other, the new realization of a large auditorium and place of worship, which is placed longitudinally to create a visual tension towards the wide space of the courtyard and the historical architectures. The result is an architectural design that preserves the rural vocation of the original structures and their contextualization in the courtyard complex in which they are inserted, but at the same time amply satisfies the Client’s request by providing the necessary distribution solutions for each functional destination and ensuring perfect usability of the new spaces through innovative expressiveness. The new auditorium building, covered with a gold-colored copper skin and surrounded by a park and bordered by a water basin, has a capacity of 1,000 seats in the configuration of both a worship hall and a conference hall. The large hall is well insulated from the outside, visually, acoustically and thermally, dedicated to prayer and meetings with the possibility of the aid of projections and music. As with the built-up parts, the ground arrangements and green parts also follow criteria of utmost respect for the origins of the place, together with a general attention to the use of environmentally friendly materials and whose production has a reduced rate of energy consumption and harmful air emissions.

The plant design involved two substantially different interventions: the realization of the systems serving the newly constructed building and the realization of the systems serving existing buildings, some of which are constrained by the Superintendence. The main objective of the project was to realize facilities that, in addition to achieving the comfort optimal user comfort and economy and ease of operation from an energy and maintenance point of view, respect the architectural appearance as much as possible. From this point of view, the systems are designed not to appear, and to be as integrated as possible into the valuable architectural artifacts. As far as ventilation is concerned, the primary air system was used both for heating in winter and for conveying fresh air flows in summer, placing the air handling unit in a room behind the Shumidan hall. Both heat and cold are produced by an inverter heat pump system that uses groundwater extracted from two new wells. As for the lighting system, the Shumidan is equipped with a tower that stands out beyond the hall’s large varied-geometry roof to allow the introduction from above and from the northeast of natural light through motorized screens and openings, an opening that in the midseasons, thanks to the “Venturi” effect, also allows effective ventilation and natural air exchange without energy consumption.

The structural design on the pre-existence mainly involved: the consolidation of the wooden trusses and coffered ceilings; the total renovation of wooden doors and window frames replaced with steel profiles (bronze-colored, with high insulation performance); the construction of new openings with typical metal lintel interventions; the closure of existing openings with a new masonry infill adequately bonded to the existing masonry; the seaming of load-bearing masonry not currently bonded by means of reinforcing bar grouting interventions with fluid cement mortar to compensate for volume; “sew-ins” interventions for significant through-joints and deep joint stitching interventions.